The advancement in technology has allowed the production of wood pellets on a small scale. The rising demand for pellet heating over the past couple of years has made many people seek the skills for making pellets for their own use, instead of having to buy commercially made pellets. One important requirement in the making of pellets is a pellet machine. Apart from this machine, one also needs a hammer mill, among other simple tools.

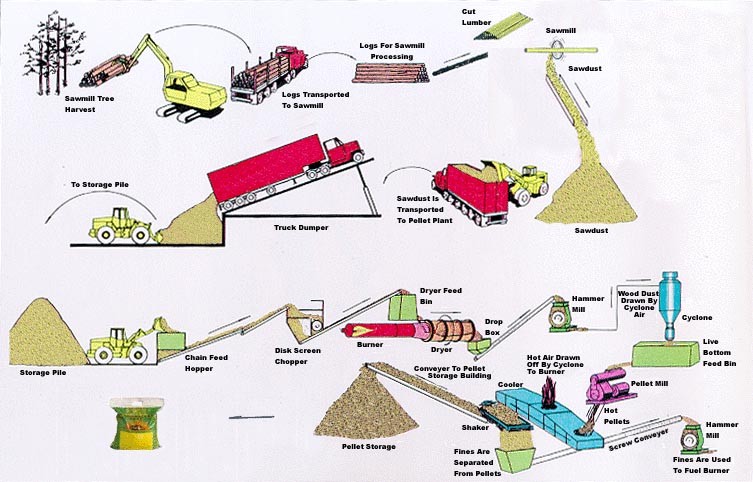

Pellets are made by compressing wood or other forms of biomass into pellet form. That is why some people refer to the pellet machines as pellet presses. The process of making these pellets is not that complex, provided you have the right tools and raw materials. Therefore, you must have the raw materials, which include wood chipping, or grasses, agricultural waste, grains, or any other form of biomass. If you have large pieces of wood, you must first use a hammer mill or chipper to break them down.

The wood to be pelletized should first be dried, but leave a small fraction of the moisture content i.e. 10-20%. You may dry this wood naturally or use a dryer to hasten the drying process. You may also require binding agents such as vegetable oil, flour, or cornstarch, especially if the raw materials you are working with do not contain sufficient natural binding compounds, and the pellet mill that you are using does not produce the require heat levels during pelletization.

During the pellet production process, the pellet mill presses the raw material into a die, by using a roller. The pellets thus formed will take the size and shape of the holes within the die. This process produces a lot of heat, due to the friction and pressure involved. This heat is important since it melts the binding agent into the wood.